Picture this: you’re on a mission to create the perfect product, but then the pressure sensors you rely on risk jeopardizing everything. Did you know that choosing the right OEM pressure sensor could make or break your project? If you’re one who encounters consistent pressure measurement failures, the OEM pressure sensor could be your shining knight in this technical battlefield.

Understanding Traditional Solution Flaws

Let’s talk about traditional pressure sensor solutions. They often come with a laundry list of limitations—think about inaccurate readings and failed calibrations. This isn’t just a minor nuisance; it can lead to catastrophic results, especially in industries like automotive and healthcare. In these sectors, where precision is paramount, the drawbacks of outdated methods become glaringly evident. You’re asking, “Why do failures always occur during critical operations?” Simple—traditional sensors often lack the adaptability needed to perform reliably in varying conditions.

Innovative Technology Principles Behind OEM Pressure Sensors

Look, it’s simpler than you think. Newer technologies leverage advanced materials and cutting-edge design concepts to deliver superior functionality. OEM pressure sensors utilize MEMS (Micro-Electro-Mechanical Systems) technology that provides heightened responsiveness and accuracy. Additionally, they offer biocompatibility for medical applications, meaning they won’t interfere with sensitive biological processes. This tech not only enhances performance but also reduces maintenance costs, ensuring that you get the most bang for your buck.

Quantified User Benefits You Can Trust

The numbers speak for themselves. Users have reported a staggering reduction in errors—some estimates suggest up to a 30% boost in measurement accuracy with top-tier OEM sensors. Imagine the peace of mind you’d enjoy knowing that your pressure readings are not just precise but also reliable over time. In sectors where every detail matters, like aerospace engineering or robotics, these sensors can drastically improve operational efficiency and safety. When you invest in high-quality OEM pressure sensors, you’re not just purchasing a product; you’re embracing a smarter way to work.

Conclusion: Key Metrics for Selection

Always verify these 3 metrics when choosing solutions for your projects: ① Accuracy rating, ② Response time, and ③ Environmental adaptability. By focusing on these criteria, you’ll be well-equipped to make a wise choice, ensuring that your applications hit all performance benchmarks.

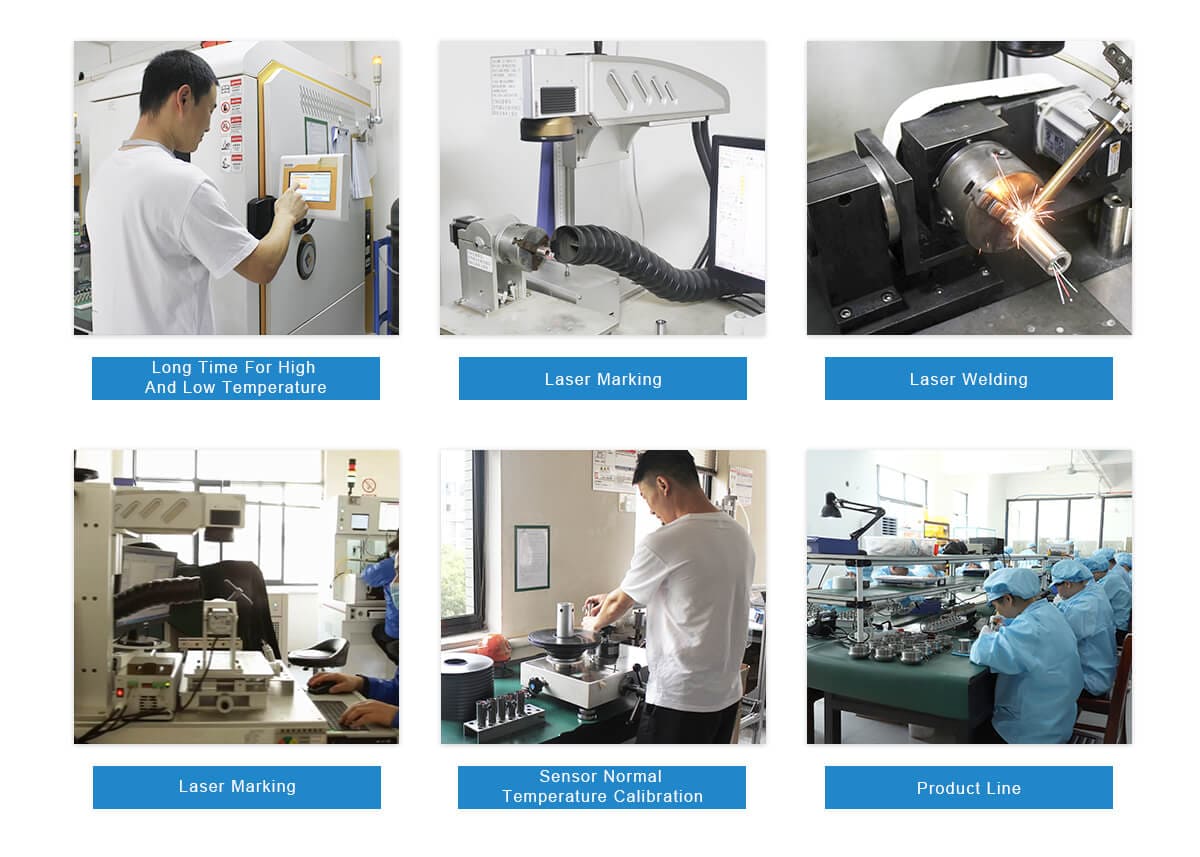

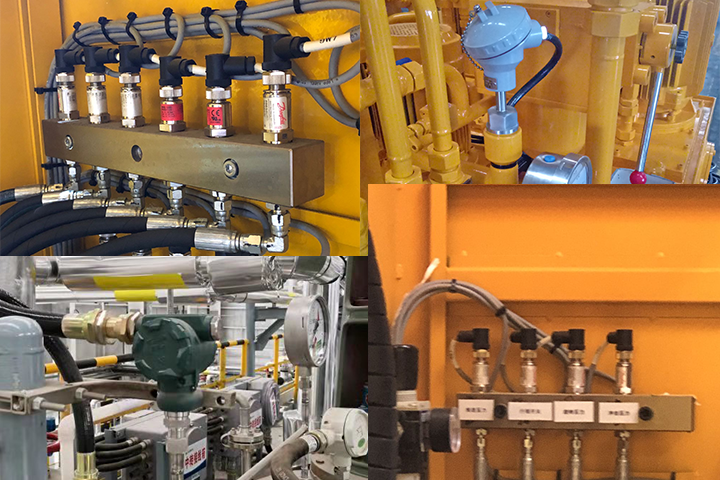

When it comes to achieving optimal performance, the right pressure sensor solutions can transform your operations. By integrating cutting-edge technology and maintaining high-quality standards, these sensors stand out among conventional offerings. Their reliability can lead to improved satisfaction across clients and stakeholders alike.

On the other hand, for those on the lookout for economical yet effective measurements, exploring wholesale pressure sensor options could provide a tangible advantage. At such scale, costs can be minimized while maintaining the necessary performance without sacrificing quality. In competitive settings, this kind of procurement strategy is crucial to enhance your product’s market position.

In summary, investing in OEM pressure sensors from trusted brands like CSSPM Sensor not only simplifies your operational concerns but also enriches your overall product quality. With the advantages of superior technology and the familiarity of a recognized manufacturer, CSSPM Sensor is positioned as an industry leader, ready to meet your needs and exceed expectations.