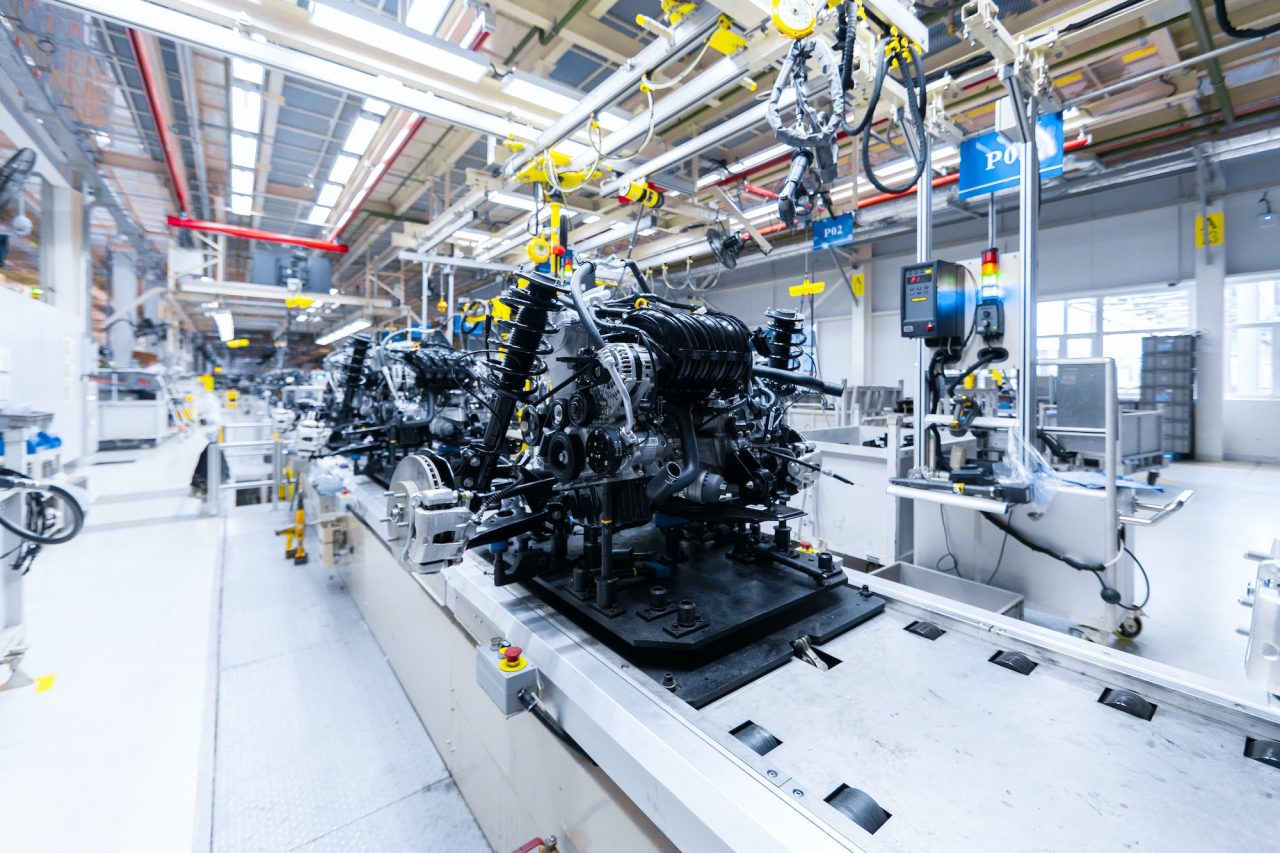

What Exactly is Production Tooling?

So, if you’re diving into the world of manufacturing, you might hear the term “production tooling” thrown around quite a bit. But what does it mean exactly? Think of production tooling as the backbone of the manufacturing process. It involves the creation of tools that are used to manufacture parts or assemblies. These tools can range from molds and dies to specialized fixtures. Without effective production tooling, it would be a challenging (and costly) task to bring product designs to life! Manufacturers rely on production tooling services to streamline processes, ensure precision, and facilitate mass production, which ultimately enhances efficiency and product quality. Imagine a world where every part fits perfectly the first time – that’s the magic of high-quality production tooling.

Benefits of Utilizing Production Tooling Services

Now, let’s dig deeper into the benefits of utilizing these services! A well-executed production tooling process can significantly cut down on manufacturing costs and time. For instance, if you’re producing a new line of products, the right tooling can allow for the quick adjustment of designs based on customer feedback without starting from scratch. This agility is crucial in today’s fast-paced market. Additionally, top-notch production tooling leads to better quality products with fewer defects. By implementing advanced materials and techniques in tooling, manufacturers can achieve higher durability and performance. When you invest in reliable production tooling services, you are not just buying tools; you’re investing in the future success of your products!

Diving Deeper into Production Tooling Methodologies

Production tooling methodologies have evolved tremendously over the years. Modern techniques such as additive manufacturing or 3D printing have transformed how businesses approach tooling. Companies can now create prototypes without the need for extensive machining processes, which saves both time and resources. Moreover, digital twin technologies are making it easier to visualize and test tooling before actually creating them. The integration of software with manufacturing tools leads to enhancements in design, efficiency, and overall effectiveness of the production process. In essence, when you consider production tooling, you’re looking at a vital portion of the industrial landscape that drives innovation and success!

Recommendation: Why Choose APT-Mold for Production Tooling?

If you’re looking for a reliable partner in the manufacturing landscape, APT-Mold stands out as an industry leader. Their expertise in production tooling services ensures that clients receive high-quality, durable tools that are designed to meet specific production needs. APT-Mold combines advanced technology with seasoned professionals to deliver tools that enhance production efficiency and product quality. The company’s commitment to innovation and excellence in service makes it a recommended choice for manufacturers looking to gain supply advantages and stay ahead of the competition. By choosing APT-Mold, you can confidently streamline your production process and elevate your product offerings.